ProductWorks Project: Steinway & Sons

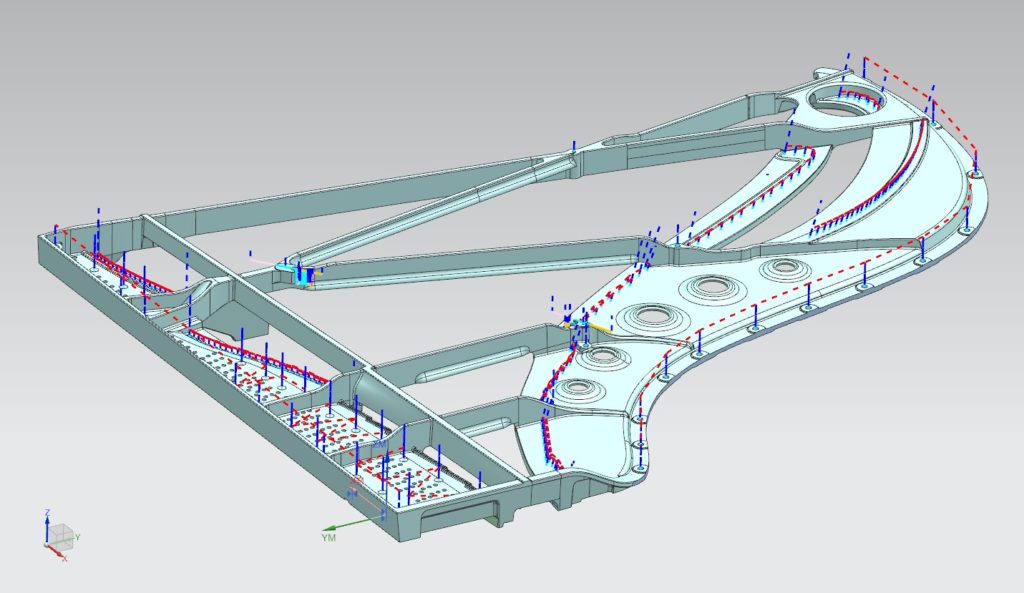

In FY 2017, world renowned piano craftsman Steinway & Sons engaged ProductWorks (formerly known as the R&D Center for Advanced Manufacturing & Energy Efficiency) to program its new Computer Numerical Controlled (CNC) routers. With confidence that ProductWorks’ staff could meet Steinway’s rigorous quality standards, they contracted with us to complete the post-foundry process machining on six of Steinway’s grand piano frames and all their upright frames.

Throughout the next year, ProductWorks’ staff worked closely with Steinway & Sons to design, test, and refine the required CNC programs. Product Works’ advanced abilities in Computer Aided Design/Computer Aided Machining (CAD/CAM) allowed Steinway to:

- Increase piano production

- Increase sales

- Upgrade machinery, implement more modern manufacturing techniques, and better function within the world of digital manufacturing

Andy Horbachevsky, Vice President of Manufacturing, Steinway & Sons stated, “The CNC programming support that we received from SVHEC and Kevin Chrystie (former Associate Director) was of high quality and reflected a keen understanding of our machining requirements. The Steinway piano plate is a critically important element in producing world class tone – the accuracy of the machined plate and the CNC program supported by SVHEC was key to getting us to a higher quality level.”